Description

Microsystem engineers research, design, develop, and supervise the production of microelectromechanical systems (MEMS), which can be integrated in mechanical, optical, acoustic, and electronic products.

Excludes microelectronics engineer.

Includes people using materials such as quartz, plastics and ceramics.

Duties

Microsystem engineers typically do the following:

- Create detailed designs for MEMS devices, utilizing CAD and simulation software to develop schematics and layouts.

- Fabricate and test prototypes to evaluate the functionality, performance, and reliability of microsystems.

- Conduct rigorous testing and validation of MEMS devices to ensure they meet design specifications and quality standards.

- Develop and optimize fabrication processes, including lithography, etching, and deposition, to produce MEMS devices.

- Integrate MEMS devices with other electronic and mechanical systems to create fully functional microelectromechanical systems.

- Diagnose and resolve technical issues related to the design, fabrication, or performance of MEMS devices.

- Stay abreast of advancements in MEMS technology and apply innovative solutions to design and process challenges.

- Prepare comprehensive technical documentation, including design specifications, process guidelines, and test reports.

- Implement quality control procedures to ensure MEMS devices meet stringent performance and reliability standards.

- Work with cross-functional teams, including materials scientists, electrical engineers, and product designers, to develop integrated solutions.

- Ensure all designs and processes comply with relevant industry standards and regulatory requirements.

Other titles

The following job titles also refer to microsystem engineer:

specialist in microelectromechanical systems

microsystem engineering adviser

microsystem technology engineering consultant

engineer in microsystems

microsystem technology engineering specialist

micro-system engineer

micro systems engineer

microsystem engineering consultant

micro system engineer

microsystem technology engineer

microsystem technology engineering expert

advanced MEMS engineer

microelectromechanical systems engineer

microsystem engineering specialist

microsystem technology engineering adviser

micro-systems engineer

engineer in micro-systems

microsystems engineer

senior MEMS engineer

microsystem engineering expert

engineer of microsystems

MEMS engineer

Working conditions

Microsystem Engineers typically work in a combination of office, laboratory, and cleanroom environments. Office work involves designing and simulating MEMS devices, analyzing data, and preparing reports. Laboratory work includes testing prototypes, conducting experiments, and calibrating equipment. Cleanrooms are essential for the fabrication and testing of MEMS devices to prevent contamination and ensure high-quality production. The role requires collaboration with other engineers and professionals, necessitating strong communication skills. Standard working hours are common, but project deadlines or critical issues may require additional hours, including evenings and weekends. Adherence to safety and cleanliness protocols is crucial, especially in cleanroom settings.

Minimum qualifications

A bachelor’s degree in microsystems engineering, electrical engineering, mechanical engineering, materials science, or a related field is typically required. Advanced degrees or specialized training in MEMS technology, nanotechnology, or microfabrication can be advantageous. Coursework in microelectronics, microfabrication techniques, sensor technology, and materials science is beneficial.

Practical experience through internships, co-op programs, or entry-level positions in microsystems engineering or related fields is highly valuable. Proficiency in using CAD software, simulation tools, and microfabrication equipment is essential. Strong analytical, problem-solving, and communication skills are crucial for designing and troubleshooting complex MEMS devices. Continuous professional development and staying updated with advancements in MEMS technology and industry standards are important for career progression. Certifications or memberships in professional organizations, such as the Institute of Electrical and Electronics Engineers (IEEE) or the American Society of Mechanical Engineers (ASME), can enhance job prospects and credibility in the field.

ISCO skill level

ISCO skill level is defined as a function of the complexity and range of tasks and duties to be performed in an occupation. It is measured on a scale from 1 to 4, with 1 the lowest level and 4 the highest, by considering:

- the nature of the work performed in an occupation in relation to the characteristic tasks and duties

- the level of formal education required for competent performance of the tasks and duties involved and

- the amount of informal on-the-job training and/or previous experience in a related occupation required for competent performance of these tasks and duties.

Microsystem engineer is a Skill level 4 occupation.

Microsystem engineer career path

Similar occupations

These occupations, although different, require a lot of knowledge and skills similar to microsystem engineer.

sensor engineer

microelectronics engineer

electromagnetic engineer

electromechanical engineer

optomechanical engineer

Essential knowledge and skills

Essential knowledge

This knowledge should be acquired through learning to fulfill the role of microsystem engineer.

- Electricity principles: Electricity is created when electric current flows along a conductor. It entails the movement of free electrons between atoms. The more free electrons in a material, the better it conducts. The three main parameters of electricity are voltage, current (ampère), and resistance (ohm).

- Engineering principles: The engineering elements like functionality, replicability, and costs in relation to the design and how they are applied in the completion of engineering projects.

- Design drawings: Understand design drawings detailing the design of products, tools, and engineering systems.

- Electrical engineering: Understand electrical engineering, a field of engineering that deals with the study and application of electricity, electronics, and electromagnetism.

- Mathematics: Mathematics is the study of topics such as quantity, structure, space, and change. It involves the identification of patterns and the formulation of new conjectures based on them. Mathematicians strive to prove the truth or falsity of these conjectures. There are many fields of mathematics, some of which are widely used for practical applications.

- Microsystem test procedures: The methods of testing the quality, accuracy, and performance of microsystems and microelectromechanical systems (MEMS) and their materials and components before, during, and after the building of the systems, such as parametric tests and burn-in tests.

- Physics: The natural science involving the study of matter, motion, energy, force and related notions.

- Environmental legislation: The environmental policies and legislation applicable in a certain domain.

- Environmental threats: The threats for the environment which are related to biological, chemical, nuclear, radiological, and physical hazards.

- Electronics: The functioning of electronic circuit boards, processors, chips, and computer hardware and software, including programming and applications. Apply this knowledge to ensure electronic equipment runs smoothly.

- Mechanical engineering: Discipline that applies principles of physics, engineering and materials science to design, analyse, manufacture and maintain mechanical systems.

- Microassembly: The assembly of nano, micro or mesoscale systems and components with dimensions between 1 µm to 1 mm. Because of the need for precision on a microscale, micro assemblies require reliable visual alignment equipment, such as ion beam imaging systems and stereo electronic microscopes, as well as precision tools and machines, such as microgrippers. The microsystems are assembled according to techniques of doping, thin films, etching, bonding, microlithography, and polishing.

- Microelectromechanical systems: Microelectromechanical systems (MEMS) are miniaturised electromechanical systems made using processes of microfabrication. MEMS consists of microsensors, microactuators, microstructures, and microelectronics. MEMS can be used in a range of appliances, such as inkjet printer heads, digital light processors, gyroscopes in smartphones, accelerometers for airbags, and miniature microphones.

- Electricity: Understand the principles of electricity and electrical power circuits, as well as the associated risks.

Essential skills and competences

These skills are necessary for the role of microsystem engineer.

- Conduct literature research: Conduct comprehensive and systematic research of information and publications on a specific topic. Present a comparative evaluative literature summary.

- Test microelectromechanical systems: Test microelectromechanical systems (MEMS) using appropriate equipment and testing techniques, such as thermal shock tests, thermal cycling tests, and burn-in tests. Monitor and evaluate system performance and take action if needed.

- Perform data analysis: Collect data and statistics to test and evaluate in order to generate assertions and pattern predictions, with the aim of discovering useful information in a decision-making process.

- Record test data: Record data that has been identified specifically during preceding tests in order to verify that outputs of the test produce specific results or to review the reaction of the subject under exceptional or unusual input.

- Conduct quality control analysis: Conduct inspections and tests of services, processes, or products to evaluate quality.

- Adjust engineering designs: Adjust designs of products or parts of products so that they meet requirements.

- Perform scientific research: Gain, correct or improve knowledge about phenomena by using scientific methods and techniques, based on empirical or measurable observations.

- Use technical drawing software: Create technical designs and technical drawings using specialised software.

- Analyse test data: Interpret and analyse data collected during testing in order to formulate conclusions, new insights or solutions.

- Develop microelectromechanical system test procedures: Develop testing protocols, such as parametric tests and burn-in tests, to enable a variety of analyses of microelectromechanical (MEM) systems, products, and components before, during, and after the microsystem’s construction.

- Read engineering drawings: Read the technical drawings of a product made by the engineer in order to suggest improvements, make models of the product or operate it.

- Design prototypes: Design prototypes of products or components of products by applying design and engineering principles.

- Design microelectromechanical systems: Design and develop microelectromechanical systems (MEMS), such as microsensing devices. Make a model and a simulation using technical design software to assess the viability of the product and examine the physical parameters to ensure a successful production process.

- Abide by regulations on banned materials: Comply with regulations banning heavy metals in solder, flame retardants in plastics, and phthalate plasticisers in plastics and wiring harness insulations, under EU RoHS/WEEE Directives and China RoHS legislation.

- Report analysis results: Produce research documents or give presentations to report the results of a conducted research and analysis project, indicating the analysis procedures and methods which led to the results, as well as potential interpretations of the results.

- Operate scientific measuring equipment: Operate devices, machinery, and equipment designed for scientific measurement. Scientific equipment consists of specialised measuring instruments refined to facilitate the acquisition of data.

- Prepare production prototypes: Prepare early models or prototypes in order to test concepts and replicability possibilities. Create prototypes to assess for pre-production tests.

- Approve engineering design: Give consent for the finished engineering design to proceed to the actual manufacturing and assembly of the product.

Optional knowledge and skills

Optional knowledge

This knowledge is sometimes, but not always, required for the role of microsystem engineer. However, mastering this knowledge allows you to have more opportunities for career development.

- Circuit diagrams: Read and comprehend circuit diagrams showing the connections between the devices, such as power and signal connections.

- Precision mechanics: Precision or fine mechanics is a subdiscipline in engineering that focuses on the design and development of smaller precision machines.

- Microelectronics: Microelectronics is a subdiscipline of electronics and relates the study, design, and manufacture of small electronic components, such as microchips.

- Firmware: Firmware is a software program with a read-only memory (ROM) and a set of instructions that is permanently inscribed on a hardware device. Firmware is commonly used in electronic systems such as computers, mobile phones, and digital cameras.

- MOEM: Micro-opto-electro-mechanics (MOEM) combines microelectronics, microoptics and micromechanics in the development of MEM devices with optical features, such as optical switches, optical cross-connects, and microbolometers.

- Programmable logic controller: Programmable logic controllers, or PLCs, are computer control systems used for monitoring and controlling input and output and automating electromechanical processes.

- Sensors: Sensors are transducers that can detect or sense characteristics in their environment. They detect changes in the apparatus or environment and provide a corresponding optical or electrical signal. Sensors are commonly divided in six classes: mechanical, electronic, thermal, magnetic, electrochemical, and optical sensors.

- CAE software: The software to perform computer-aided engineering (CAE) analysis tasks such as Finite Element Analysis and Computional Fluid Dynamics.

- Computer engineering: Engineering discipline that combines computer science with electrical engineering to develop computer hardware and software. Computer engineering occupies itself with electronics, software design, and the integration of hardware and software.

- Quality standards: The national and international requirements, specifications and guidelines to ensure that products, services and processes are of good quality and fit for purpose.

- Nanotechnology: Technologies, science, and engineering activities conducted on a nanoscale, where material or extremely small components are manipulated on an atomic, molecular, or supramolecular scale.

- Microoptics: Optical devices with a size of 1 millimeter or smaller, such as microlenses and micromirrors.

- Micromechanics: The design and production of micromechanisms. Micromechanisms combine mechanical and electrical components in a single device that is less than 1mm across.

- Precision measuring instruments: Instruments used for precision measuring or manufacture, such as micrometers, calipers, gauges, scales, and microscopes.

- Control engineering: Subdiscipline of engineering that focuses on controlling the behaviour of systems through the use of sensors and actuators.

- Biomedical engineering: The biomedical engineering processes used to create medical devices, prostheses and in treatments.

- Semiconductors: Semiconductors are essential components of electronic circuits and contain properties of both insulators, such as glass, and conductors, such as copper. Most semiconductors are crystals made of silicon or germanium. By introducing other elements in the crystal through doping, the crystals turn into semiconductors. Depending on the amount of electrons created by the doping process, the crystals turn into N-type semiconductors, or P-type semiconductors.

- Optoelectronics: Branch of electronics and optics dedicated to the study and use of electronic devices that detect and control light.

- Microsensors: Devices with a size smaller than 1 mm that can convert a non-electric signal, such as temperature, into an electrical signal. Because of their size, microsensors offer better accuracy, range, and sensitivity compared to larger sensors.

- Automation technology: Set of technologies that make a process, system, or apparatus operate automatically through the use of control systems.

Optional skills and competences

These skills and competences are sometimes, but not always, required for the role of microsystem engineer. However, mastering these skills and competences allows you to have more opportunities for career development.

- Provide technical documentation: Prepare documentation for existing and upcoming products or services, describing their functionality and composition in such a way that it is understandable for a wide audience without a technical background and compliant with defined requirements and standards. Keep documentation up to date.

- Communicate with customers: Respond to and communicate with customers in the most efficient and appropriate manner to enable them to access the desired products or services, or any other help they may require.

- Apply soldering techniques: Apply and work with a variety of techniques in the process of soldering, such as soft soldering, silver soldering, induction soldering, resistance soldering, pipe soldering, mechanical and aluminium soldering.

- Assemble microelectromechanical systems: Build microelectromechanical systems (MEMS) using microscopes, tweezers, or pick-and-place robots. Slice substrates from single wafers and bond components onto the wafer surface through soldering and bonding techniques, such as eutectic soldering and silicon fusion bonding (SFB). Bond the wires through special wire bonding techniques such as thermocompression bonding, and hermetically seal the system or device through mechanical sealing techniques or micro shells. Seal and encapsulate the MEMS in a vacuum.

- Define manufacturing quality criteria: Define and describe the criteria by which data quality is measured for manufacturing purposes, such as international standards and manufacturing regulations.

- Create technical plans: Create detailed technical plans of machinery, equipment, tools and other products.

- Use CAM software: Use computer-aided manufacturing (CAM) programmes to control machinery and machine tools in the creation, modification, analysis, or optimisation as part of the manufacturing processes of workpieces.

- Coordinate engineering teams: Plan, coordinate and supervise engineering activities together with engineers and engineering technicians. Ensure clear and effective channels of communication across all departments. Make sure the team is aware of the standards and objectives of the research and development.

- Use precision tools: Use electronic, mechanical, electric, or optical precision tools for precision work.

- Draft bill of materials: Set up a list of materials, components, and assemblies as well as the quantities needed to manufacture a certain product.

- Use CAD software: Computer-aided design (CAD) systems can assist in creating, modifying, analysing, or optimising a design.

- Apply technical communication skills: Explain technical details to non-technical customers, stakeholders, or any other interested parties in a clear and concise manner.

- Perform project management: Manage and plan various resources, such as human resources, budget, deadline, results, and quality necessary for a specific project, and monitor the project’s progress in order to achieve a specific goal within a set time and budget.

- Program firmware: Program permanent software with a read-only memory (ROM) on a hardware device, such as an integrated circuit.

- Operate precision machinery: Operate machinery used for the making of small systems or components with a high level of precision.

- Build business relationships: Establish a positive, long-term relationship between organisations and interested third parties such as suppliers, distributors, shareholders and other stakeholders in order to inform them of the organisation and its objectives.

- Maintain safe engineering watches: Observe principles in keeping an engineering watch. Take over, accept and hand over a watch. Perform routine duties undertaken during a watch. Maintain the machinery space logs and the significance of the readings taken. Observe safety and emergency procedures. Observe safety precautions during a watch and take immediate actions in the event of fire or accident, with particular reference to oil systems.

- Train employees: Lead and guide employees through a process in which they are taught the necessary skills for the perspective job. Organise activities aimed at introducing the work and systems or improving the performance of individuals and groups in organisational settings.

- Process customer orders: Handle orders placed by customers. Receive the customer order and define a list of requirements, a working process, and a time frame. Execute the work as planned.

- Prepare assembly drawings: Create the drawings that identify the different components and materials, and that provide instructions as to how they should be assembled.

- Perform resource planning: Estimate the expected input in terms of time, human and financial resources necessary to achieve the project objectives.

- Develop product design: Convert market requirements into product design and development.

Skills group distribution

ISCO group and title

2152 – Electronics engineers

References

- Microsystem engineer – ESCO

- Career Guide: Microsystem Engineer – Role Catcher

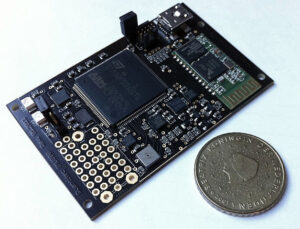

- Featured image: By Haraldino80 – Own work, CC BY-SA 3.0